Introduction to Rogers Foam and Poron Foam

The core of Rogers foam is the Poron® series (microcellular polyurethane PU foam), a registered trademark of Rogers Corporation and the benchmark for engineered foam; other elastomer materials include BISCO® silicone foam. Poron is renowned for its minimal compression set, high resilience, and superior sealing/energy absorption properties. It is extensively used in sealing, cushioning, and shielding applications across electronics, automotive, and industrial sectors, particularly suited for precision die-cutting and EMI shielding composite solutions.

Core Technical Characteristics of Poron Foam (Distinguishing It from Ordinary Foam)

1. Mechanical Properties (Core Advantages)

Ultra-low permanent compression set: Exceptionally high shape retention after prolonged compression (typically < 5%)

Superior resilience: Rapid recovery with minimal performance degradation after repeated compression cycles

Outstanding energy absorption: Efficient dispersion of impact energy

Controllable density: Selectable range of 144–480 kg/m³ to accommodate varying strength requirements

2. Environmental Adaptability

Wide Temperature Stability: Operating range -40°C to 120°C

Low Outgassing & Anti-Fogging: Minimal volatile emissions, suitable for enclosed spaces

Anti-Aging & Chemical Resistance: Resistant to ozone and hydrolysis; no brittleness or cracking during prolonged use

Halogen-Free Flame Retardancy (select grades): Meets UL94 V-0 and other safety standards

3. Processing and Application Characteristics

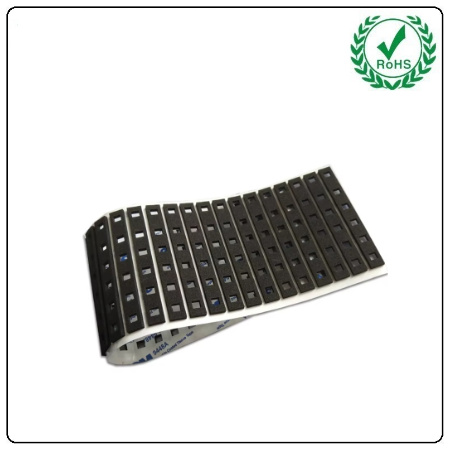

Ideal for Die-Cutting: Precisely die-cut into any shape (gaskets, liners, sealing strips) with smooth edges and tight tolerances (±0.05mm)

Easy bonding: Excellent surface wettability allows lamination with adhesive tapes (e.g., 3M, Nitto), compatible with automated application

Superior sealing performance: Achieves waterproof sealing even with perforated structures, suitable for IP protection designs

Functional lamination: Can be combined with conductive layers (copper/nickel plating) or thermal materials to integrate “shielding + thermal management + sealing + cushioning” functions

Rogers Foam's Parameter

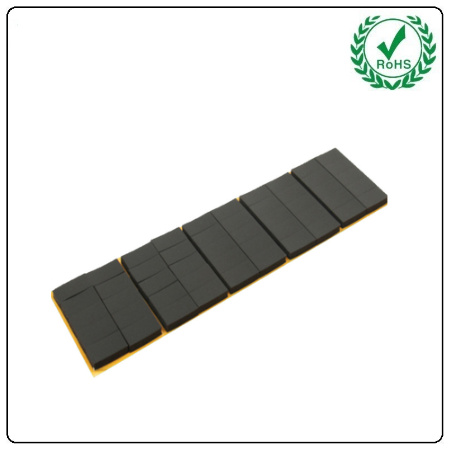

| Material | Poron foam / Rogers foam pad |

| Color | Black |

| Thickness | 0.2/0.3/0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2/2.5~10mm |

| Size/Shape | Die cut based on your requirement |

| Customzie | OEM &ODM are welcomed |

| Adhesive | Single or double sided adhesive with 3m/tesa/nitto/song or our normal one tape |

| Certificate | ISO/ Rohs approved |

| PORON | SoftSeal™ 4701-15Model Series/ PORON 4701-30 Series/ AquaPro™4701-37 Series/ 4701-41 Series/ 4701-40 Series/ 4701-50 Series/ 4701-60 Series/ ShockSeal™ 4790-79 Series/ 4790-92 Series/ SR-S Series/ H Series ect. |

| Remark | Cell closed poron with different hardness and thickness is according to you, which has antishock ,buffer, waterproof , seal , producing high quality item as result matured technology and exact Laser mold. |

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}