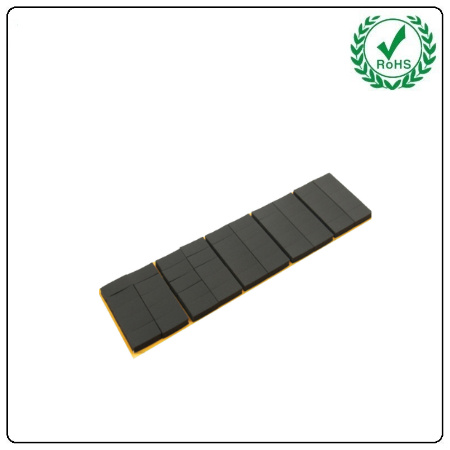

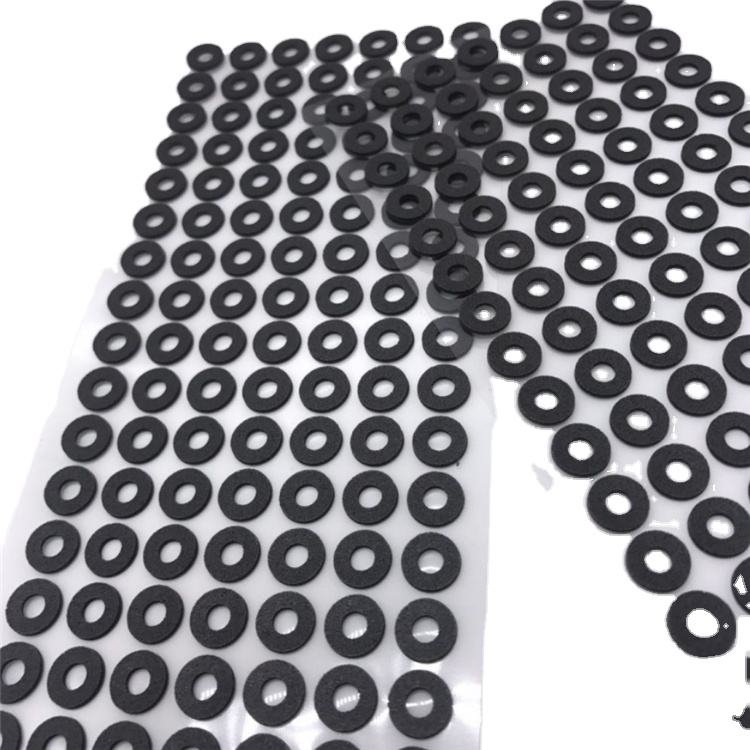

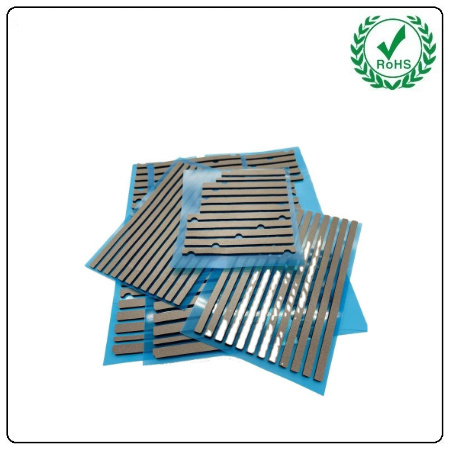

Poron gaskets can be categorized by core function into basic sealing/cushioning types, EMI shielding types, and multifunctional composite types such as flame-retardant/thermally conductive variants. They can be die-cut into customized shapes like irregular profiles, washers, or strips based on equipment structures. Some feature high-adhesion backing for automated assembly and are widely used in precision consumer electronics, automotive electronics, industrial control, and new energy sectors for gap filling, component vibration damping, electromagnetic sealing, and water/dust protection.

Poron gaskets, with their low compression set, high resilience, and sealing/conductive/waterproof properties, meet the miniaturization and high-protection demands of precision electronic devices like smartphones and cameras. They address vibration damping and EMI shielding issues in general electronics while resolving challenges such as fitting tolerances in metal enclosures/components, vibration-induced rattling, and electromagnetic sealing. Select from standard, ultra-thin, or conductive variants based on specific requirements.

I. Mobile Phones Select ultra-thin / basic / conductive variants. Core applications include: Camera modules (waterproofing/dustproofing, vibration damping for enhanced imaging stability) Screens/frames (impact cushioning, crack prevention, narrow gap sealing) Batteries/internal cavities (waterproofing, vibration damping, preventing battery contact failure) Buttons/ports (waterproof protection, improved button tactile feedback) PCBs/RF zones (conductive shielding for stable communication signals)

II. Cameras Select basic/high-energy-absorption variants (low outgassing to prevent optical component contamination). Core applications include: - Lens modules (sealing for dustproofing, vibration damping to prevent barrel shift) - Body seams/mounts (dustproofing/waterproofing, reducing vibration-induced noise) - Internal precision components (vibration damping to enhance image clarity, reducing shutter operation noise) - Battery compartments/card slots (waterproofing/dustproofing for outdoor shooting environments).

III. General-Purpose Electronic Devices Select

standard/flame-retardant/conductive/adhesive-backed variants as needed, covering consumer and industrial/commercial electronics:

1. Consumer Electronics (Tablets, Laptops, Smart Wearables, TWS Earbuds): Provides screen sealing, keypad cushioning, and component vibration damping. Laptops/premium devices feature conductive shielding; wearables/earbuds emphasize waterproofing and drop protection.

2. Industrial/Commercial Electronics (Industrial PCs, Routers, Printers): Provides EMI shielding and dust protection, absorbs vibration to reduce noise, enhances RF signal transmission efficiency, and prevents paper debris/dust from infiltrating internal circuits.

IV. Metal Enclosures / Metal Components Compatible with all gasket types, addressing core challenges in metal material compatibility: - Filling enclosure gaps (eliminating assembly tolerances, providing waterproofing and dustproofing, preventing rattling noises/paint chipping from hard metal contact); Metal shielding enclosure compatibility (conductive sealing to block electromagnetic leakage); Vibration damping between metal components (preventing hard contact damage to components); Custom sealing gaskets for high-protection metal enclosures (achieving high-grade waterproofing with no performance degradation over extended use).

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}