Core Principles for Selecting Poron Gaskets

Matching application performance requirements + meeting installation/process specifications. Follow a four-step screening process: Define requirements → Select parameters → Determine specifications → Choose brand + validate. Balance compatibility and cost for industrial applications including electronics, automotive, and smart home devices.

1. First define 3 core usage requirements Load-bearing: Dynamic repeated compression (buttons, hinges) → Heavy-duty compression with permanent deformation and high resilience; Static compression (sealing, gap filling) → Heavy-duty support / sealing capability. Environmental/Protection: Water/dust resistance (check IP rating), temperature tolerance (standard -40°C to 125°C; choose wide-temperature variants for high-heat applications), exposure to oil/reagents (requires chemical-resistant variants); anti-static protection for precision electronics. Installation: Adhesive mounting → Requires foam-specific adhesive backing; Snap-fit/mechanical fastening → Focus on dimensional tolerance control.

2. Screening Core Performance Parameters (No single optimal value for key metrics; only matching)

01. Density: ≥0.6 g/cm³ (High density, support / rigid sealing); 0.2–0.6 g/cm³ (Medium-low density, cushioning / vibration damping / flexible sealing).

02. Hardness: Shore OO 20–40 (light touch switches / electronic encapsulation); Shore OO 50–70 / Shore A 20–40 (equipment sealing / structural support).

03. Compression set: Dynamic applications ≤10%, static applications ≤20% (lower values indicate superior resilience, a core Poron advantage).

04. Other considerations: For waterproofing, select closed-cell variants ≥95% closed-cell rate; for shock absorption/noise reduction, choose variants with rebound rate ≥80%.

. Confirm Specifications and Processing Requirements (for Production and Installation Compatibility)

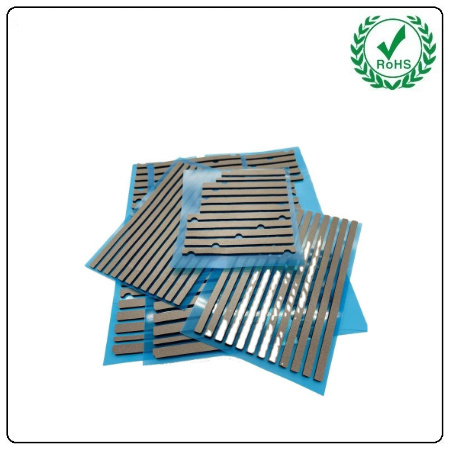

*Thickness: 0.1~10mm (Precision gap 0.1~0.5mm, large gap ≥1mm), Precision scenario tolerance ±0.05mm, Standard ±0.1mm.

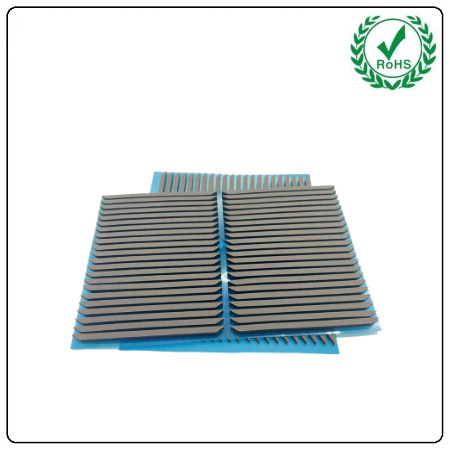

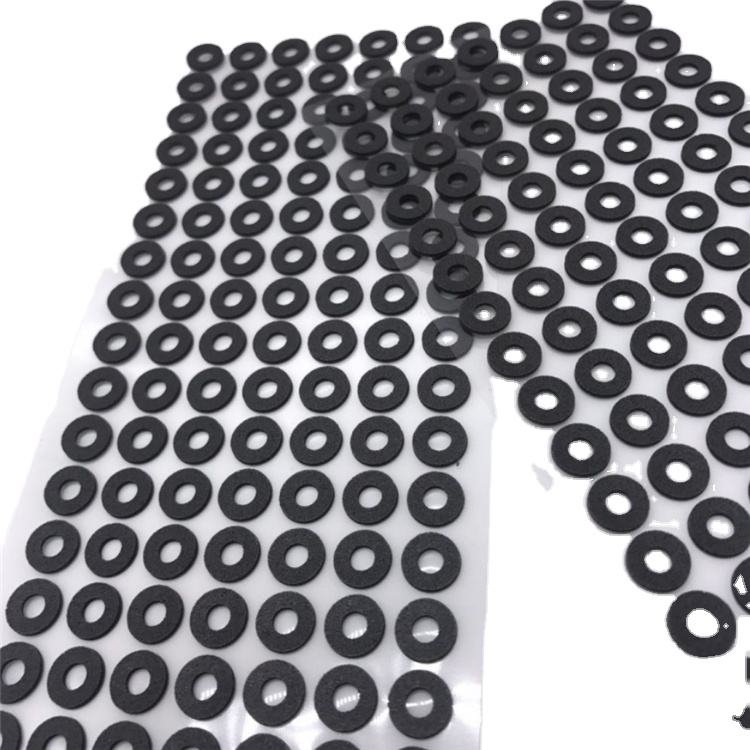

*Die-cutting: Shape determined by installation location, Precision parts tolerance ±0.05mm, Standard ±0.1mm, edges must be burr-free.

*Adhesive backing: Select foam-specific adhesive (prevents rebound/delamination). For high-temperature/metal substrates, use high-tack adhesive (e.g., 3M 467/468). For soft rubber/painted surfaces, use low-tack adhesive (prevents residue marks).

*Surface treatment: For precision electronics, choose anti-static option (surface resistance 10⁶~10¹¹Ω). For abrasion-resistant applications, select PU-coated option.

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}