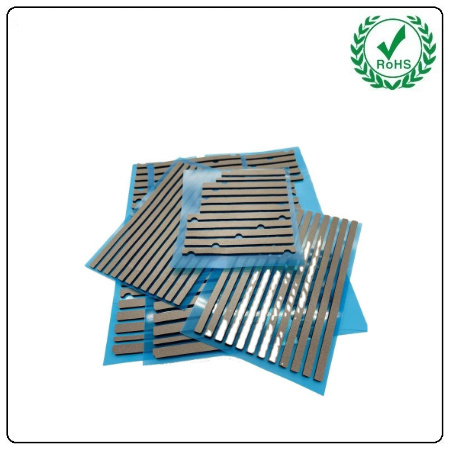

Poron gaskets utilize Rogers Poron® microcellular polyurethane foam as their base material. Leveraging its core properties of ultra-low compression set and high resilience, these gaskets generate sustained elastic recovery force through controlled compression after assembly. This enables precise gap filling in equipment while simultaneously providing sealing and cushioning functions. Conductive Poron gaskets incorporate an additional conductive layer, extending their foundational capabilities to provide EMI electromagnetic shielding. Their performance remains consistently stable across all operating conditions over extended periods.

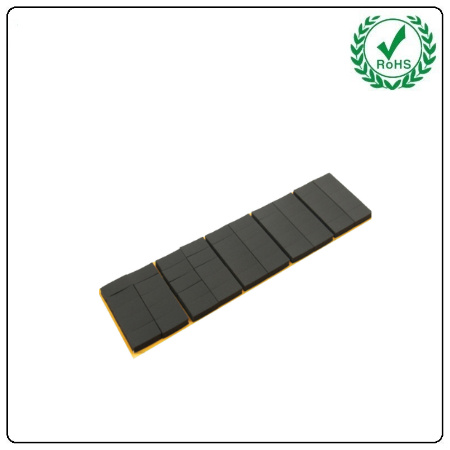

A. Basic Model (Sealing + Cushioning)

1. After assembly and compression, the gasket precisely fills irregular gaps and compensates for dimensional tolerances in equipment, eliminating sealing dead zones;

2. Continuous elastic recovery force ensures the gasket maintains tight contact with surfaces, forming a flexible sealing barrier that blocks water, dust, and gas penetration;

3. Microporous structure disperses and absorbs impact and vibration energy, protecting precision components. It retains shape and performance over extended use without degradation of sealing or cushioning effectiveness.

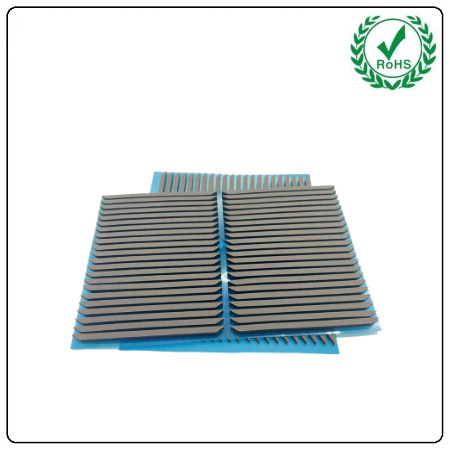

B. Conductive Model (Shielding + Sealing + Cushioning)

Building upon the operating principles of the base model, this version incorporates electromagnetic shielding logic:

1. The conductive layer within the composite gasket forms a gap-free conductive connection by compressing against the equipment's metal surface;

2. The continuous conductive layer forms a Faraday cage with the equipment's metal housing, reflecting and blocking electromagnetic waves to achieve EMI shielding;

3. The high resilience of the base material ensures long-term, tight contact between the conductive layer and the contact surface, preventing shielding effectiveness from degrading due to vibration or aging.

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}