The core operating principle of Poron Foam

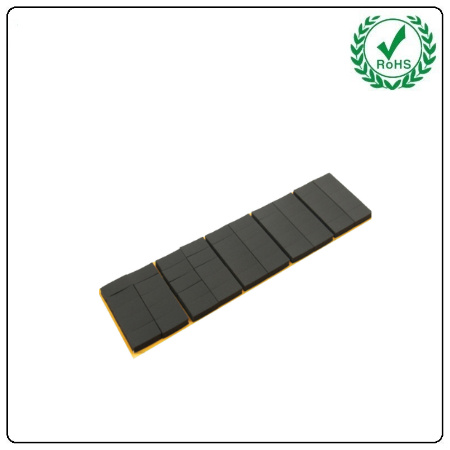

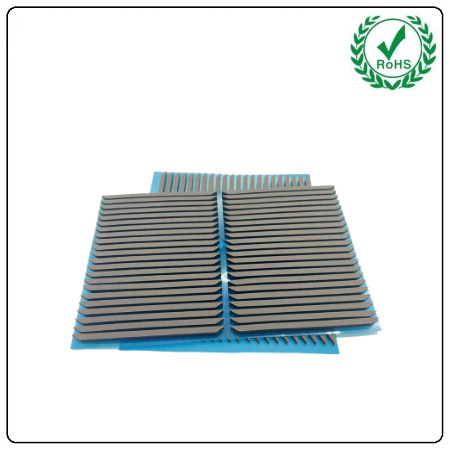

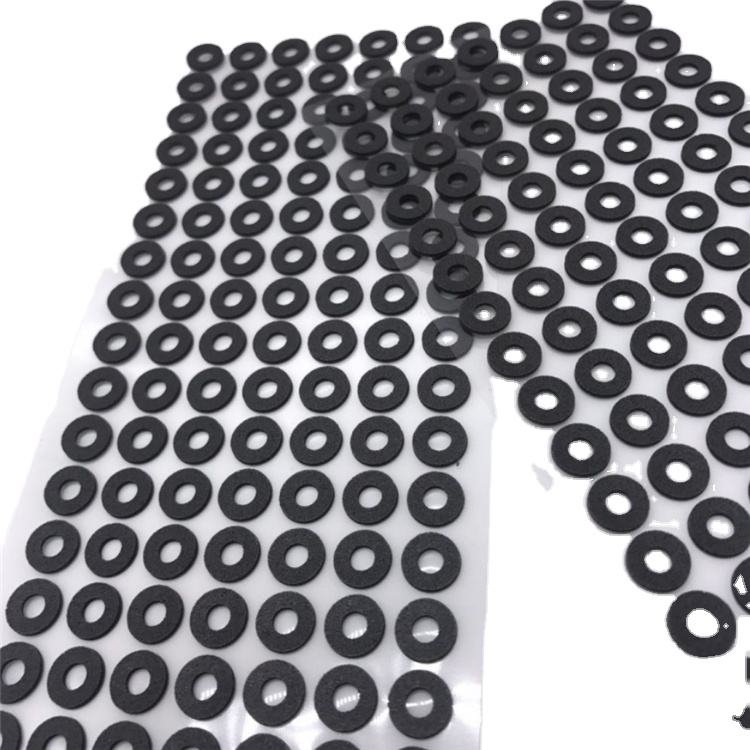

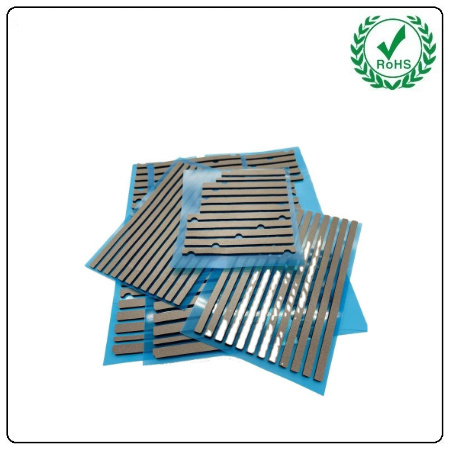

The core operating principle of Poron Gasket relies on the patented elastomer structure of Rogers Poron® microcellular polyurethane foam. Through controlled compression, it generates a sustained and stable elastic recovery force, achieving precise gap filling, sealing isolation, and mechanical cushioning for equipment. Conductive Poron Gasket builds upon this foundation by incorporating a continuous conductive layer to achieve EMI electromagnetic shielding. This integration combines material elasticity with structural adaptability, representing the core technological distinction from conventional foam gaskets. Functionally, its operating principles are categorized into two types: Basic Sealing/Cushioning and Conductive Shielding. Both rely fundamentally on the performance of the Poron substrate, augmented by the functionality of distinct layers.

Applications of Poron Gaskets

Consumer Electronics: Smartphone camera module seals, laptop keyboard cushioning pads, smartwatch waterproof gaskets. Automotive Electronics: Sealing gaskets for new energy battery packs, electromagnetic sealing pads for millimeter-wave radar, cushioning pads for in-vehicle center consoles. Industrial Equipment: Sealing gaskets for industrial control computer enclosures, vibration-damping shims for sensors, gap-filling pads for servo motors. Medical Devices: Sealing gaskets for ventilators, cushioning shims for patient monitors, prosthetic fitting pads.

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}