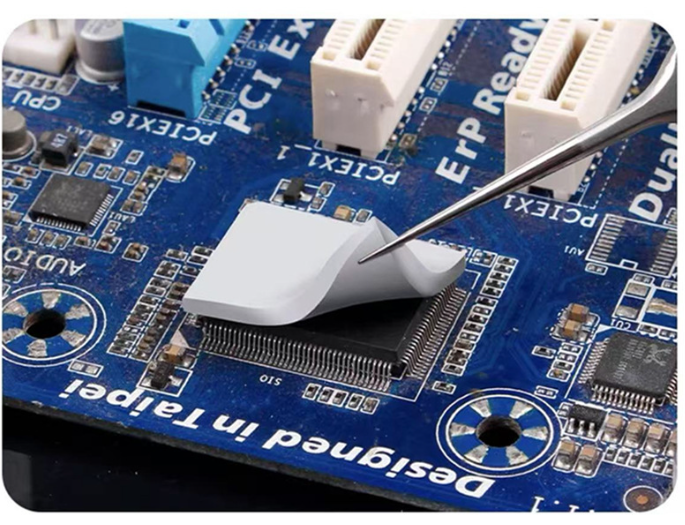

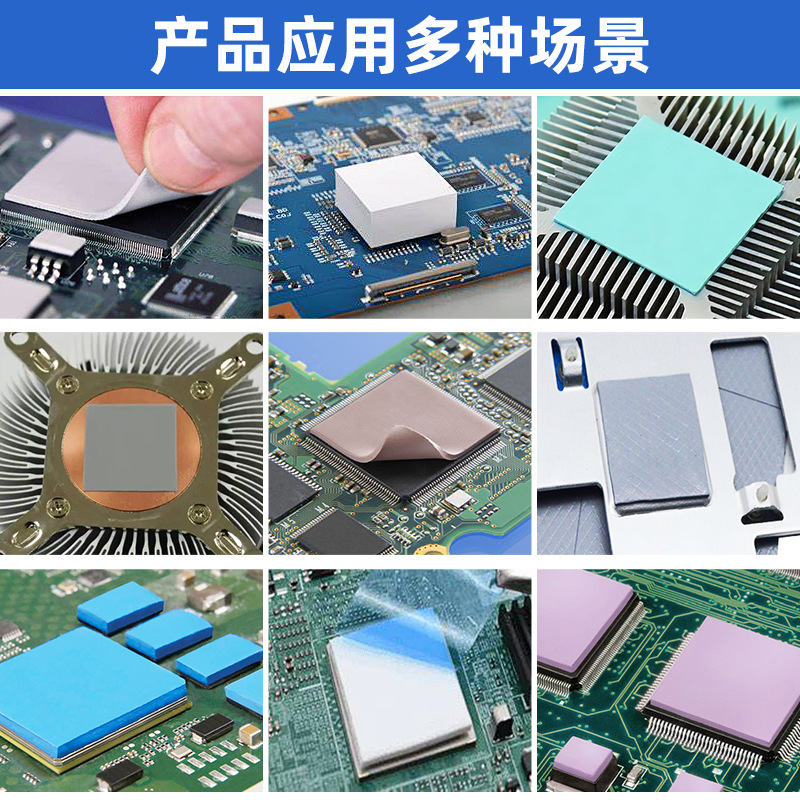

For the combination of TEC + heat sink, the silicone thermal pad is not an “optional cooling accessory” but rather a “core component for achieving efficient, safe, and long-term heat dissipation.” It simultaneously addresses four critical issues: thermal conductivity, electrical safety, deformation adaptation, and physical protection. Without this adaptation layer, the cooling performance of the TEC will significantly degrade, and there is an extremely high risk of equipment failure.

In view of the working characteristics of TEC (semiconductor cooling sheet) (large temperature difference between hot and cold ends, high requirement for efficient heat conduction, and strict electrical isolation), this type of silicone heat dissipation pad has the following key features:

1. High thermal conductivity The thermal conductivity is usually between 1.0 and 6.0 W/m·K (some high-performance models can reach above 8.0 W/m·K), which can quickly transfer the heat generated by TEC operation to the heat sink, avoiding local overheating that affects the cooling efficiency. It can meet the transient heat flow requirements of TEC, reducing thermal accumulation-induced performance degradation.

2. Reliable electrical insulation The breakdown voltage can reach above 3000V, which can effectively isolate the electrical path between TEC and the heat sink, preventing short circuits or leakage, and meeting the safety standards of electronic devices. The insulation performance remains stable within a wide temperature range, avoiding insulation failure due to temperature changes.

3. Flexible and compressible design It has excellent flexibility and resilience, with a compressibility rate usually ranging from 20% to 50%, which can fill the microscopic irregularities on the surface of TEC and the heat sink, significantly reducing the contact thermal resistance. It can adapt to the minor deformations during TEC operation, maintaining a long-term secure adhesion without peeling, and ensuring the continuity of heat conduction.

4. Wide temperature range stability The temperature resistance range covers -40℃ to 150℃, which can cope with the extreme temperature differences between the hot and cold ends of TEC, not hardening at low temperatures or flowing at high temperatures, maintaining the physical form and performance stability. It has excellent thermal shock resistance, and does not crack or show performance degradation after repeated cold and hot cycles.

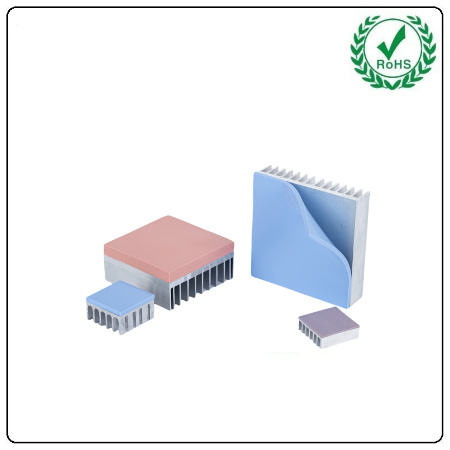

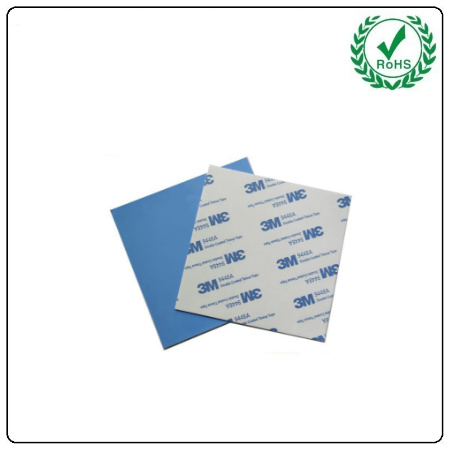

5. Convenient installation and adaptability It comes with self-adhesive or back-grip design, requiring no additional fasteners. Installation can be done by simply adhering directly, simplifying the assembly process of TEC and the heat sink. The thickness can be selected (0.5 to 5mm) and customized, and can be precisely matched according to the installation gap of TEC to optimize the compression amount to improve heat transfer efficiency.

6. Safety and durability It complies with UL94 V-0 flame retardant standard, extinguishing spontaneously when exposed to fire, reducing the risk of equipment fire. It has anti-aging, ozone resistance, and chemical corrosion resistance, and shows no significant performance degradation after long-term use (usually ≥5 years), suitable for industrial-grade high-reliability scenarios.

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}