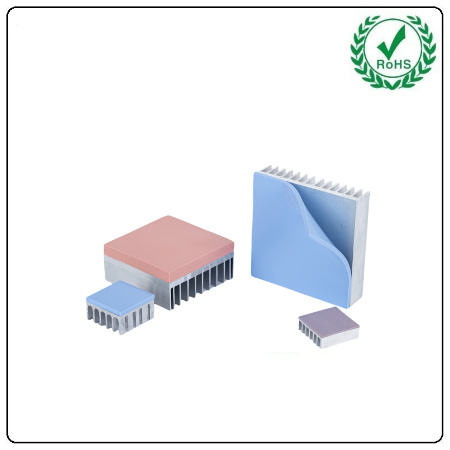

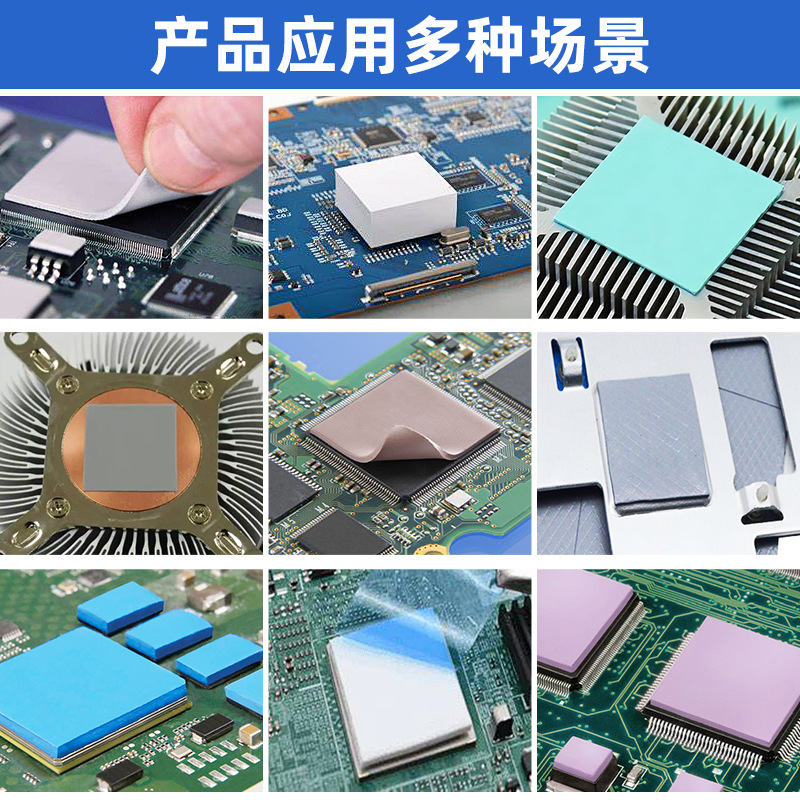

Silicone thermal pads are not an optional accessory but a must-have for achieving efficient, safe, and long-term stable heat dissipation between TEC (Thermoelectric Cooler) modules and metal heat sinks. As a dedicated adaptive layer, they precisely address the core issues of direct contact between TECs and heat sinks. The key reasons are summarized as follows:

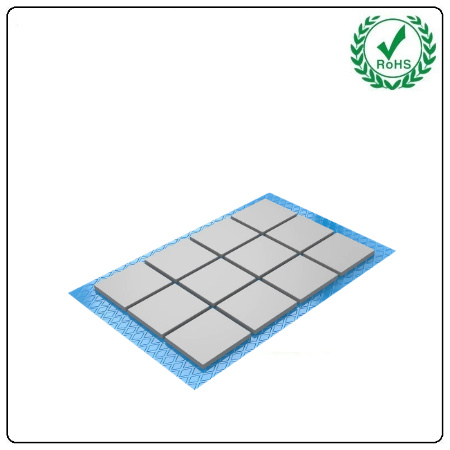

1.Significantly reduce contact thermal resistance They fill the microscopic gaps and unevenness on the TEC ceramic surface and heat sink, displacing air (a poor thermal conductor), enabling direct and efficient heat transfer, and preventing heat accumulation that would otherwise degrade cooling performance.

2.Adapt to micro-deformation from thermal cycles TECs experience large temperature differences between their hot and cold sides during operation, leading to thermal expansion and contraction. The elasticity of silicone pads maintains tight contact at all times, preventing poor thermal coupling. They also protect the brittle TEC ceramic substrate from cracking due to hard metal-to-ceramic contact.

3.Mandatory electrical insulation protection TECs have internal conductive structures, and metal heat sinks are conductive. The high insulation of silicone pads blocks electrical paths between them, eliminating the risk of short circuits and electric leakage—a non-negotiable safety requirement for electronic devices.

4.Balance localized heat transfer They mitigate the problem of localized high heat flux caused by TEC manufacturing processes, preventing sharp drops in cooling efficiency due to concentrated heat.

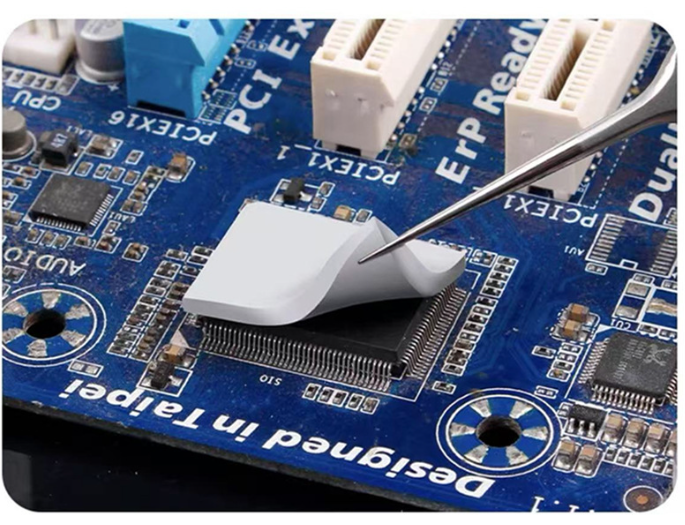

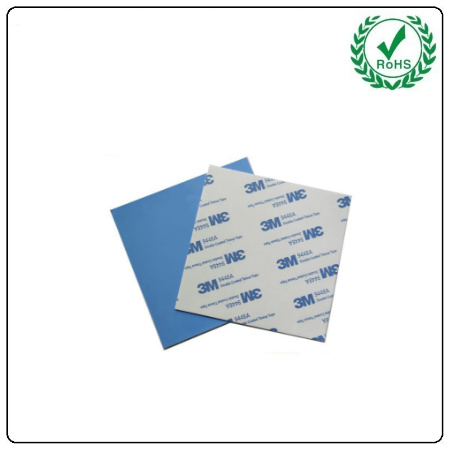

5.Physical protection & easy installation Their soft nature cushions and protects the TEC ceramic substrate from scratches and cracks. They seal gaps to block dust and moisture, extending the lifespan of both components. With self-adhesive backing and customizable thickness (0.5–5 mm), they require no additional fasteners, enabling simple assembly and precise matching of installation gaps.

Silicone thermal pads are a core essential component for TEC heat dissipation. They simultaneously solve four critical challenges: thermal conductivity, electrical safety, deformation adaptation, and physical protection. Without them, TEC cooling performance will degrade drastically, and the risk of equipment failure (e.g., short circuits, burnout) will be extremely high.

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}