The Feature of KKG Silicone Thermal Pad

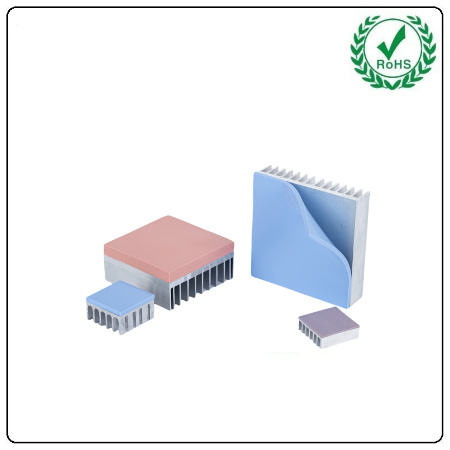

1.Excellent Flexibility,Good Adhesion

The appropriate compression ratio andsurface adhesion allow perfect fittingfilling witht meuThur dmenatheating components, greatly reducingthermal resistance.

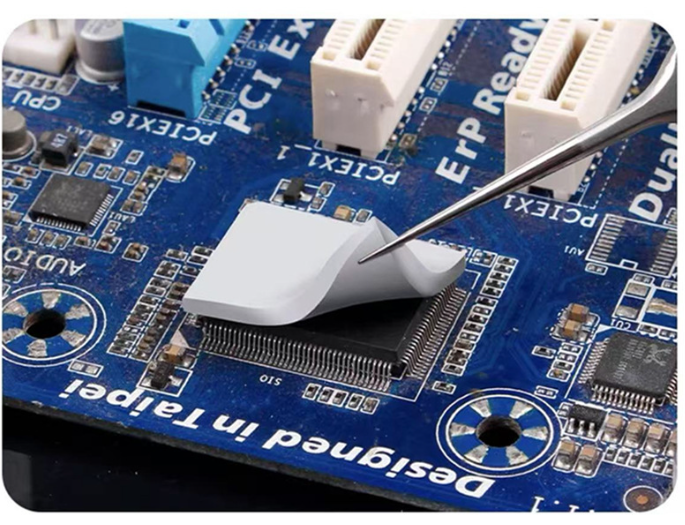

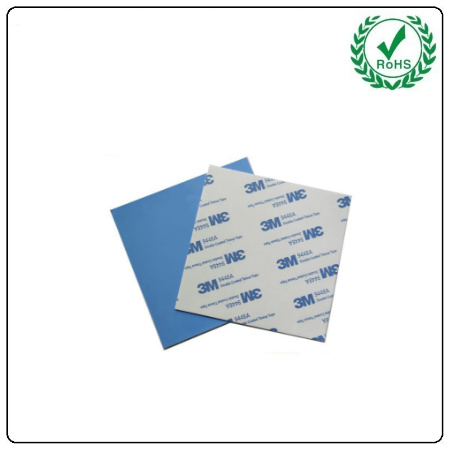

2.Ready-to-use,Customizable on Demand

Easy to use-just tear and stick for heat dissipation;customizable in various shapes, thicknesses,and sizes; fast delivery, bulk pricing available

3.Excellent Insulation & Thermal Conductivity

Provides excellent protection for electronic products. The silicone material is puncture-resistant, requires no fastening devices, and offers reliable electrical insulation.

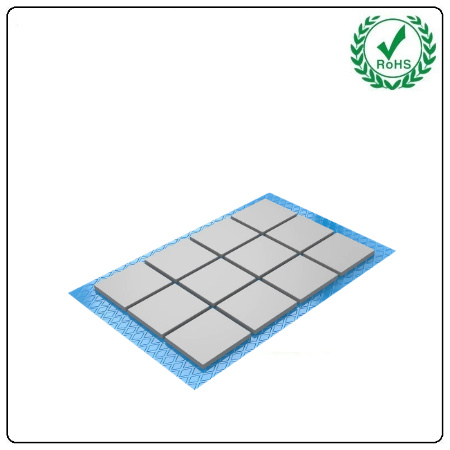

4.Precise Cutting & Exquisite Craftsmanship

Uses die-cutting technology with smooth, burr-free cuts that won’t scratch your hands.

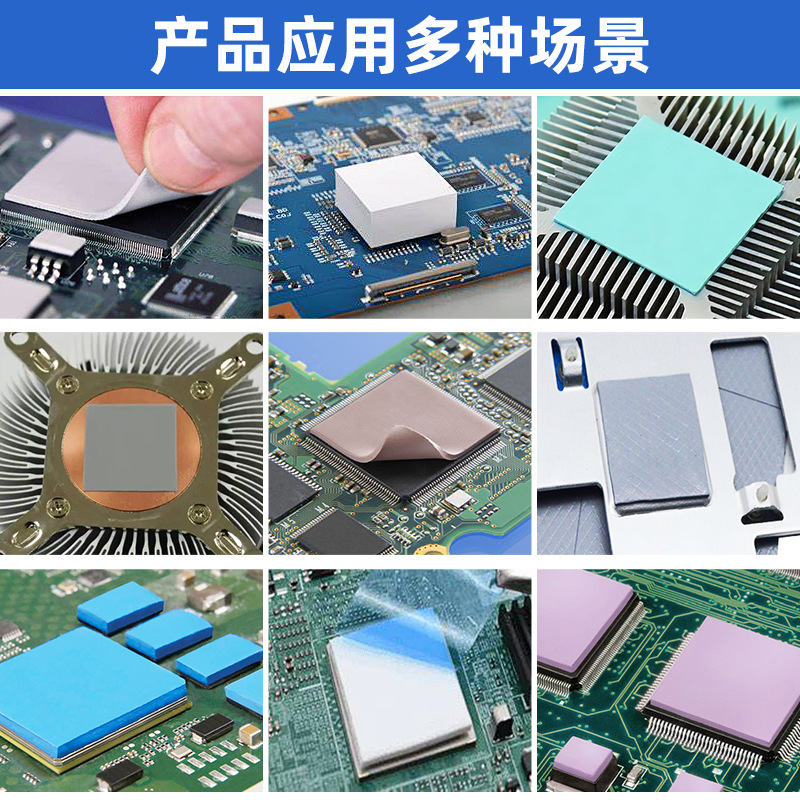

The Application of the Silicone thermal pads

Silicone thermal pads leverage their high thermal conductivity, electrical insulation, shock absorption, and compressible adaptability to serve as core components across eight major sectors:

Consumer Electronics: Smartphones, laptops, etc. – Filling gaps between chips and heat sinks to accommodate slim designs.

Automotive Electronics: New energy vehicle BMS, charging stations, and traditional in-vehicle equipment – Temperature-resistant and shockproof for stable operation.

Industrial Control Equipment: PLCs, inverters, etc. Resistant to aging and compression, maintaining thermal conductivity and insulation under high loads.

New Energy Equipment: PV inverters, energy storage battery packs. Strong insulation prevents leakage while enabling rapid heat dissipation.

LED Lighting: High-power fixtures. Solves LED chip heat dissipation challenges, extending service life.

Medical Equipment: Ultrasound machines, monitors, etc. – Eco-friendly and odorless, suitable for sterile medical environments.

Communication Equipment: Base stations, servers, etc. – Supports 24/7 uninterrupted thermal conductivity.

Semiconductor Cooling Pad Accessories: Fills gaps between hot and cold ends, reduces thermal resistance, and cushions vibrations to prevent substrate cracking.

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}