Mainstream EMI Shielding Materials and Their Characteristics

| Material Categories | Key Features | Typical Form |

|---|---|---|

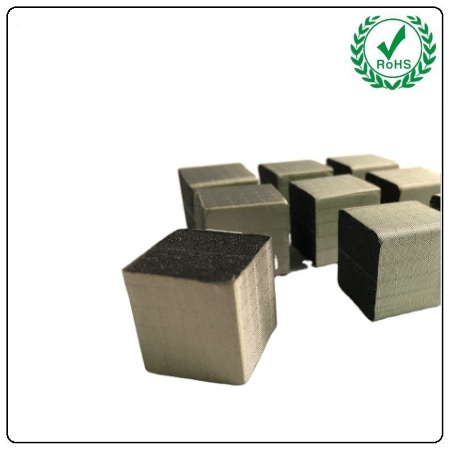

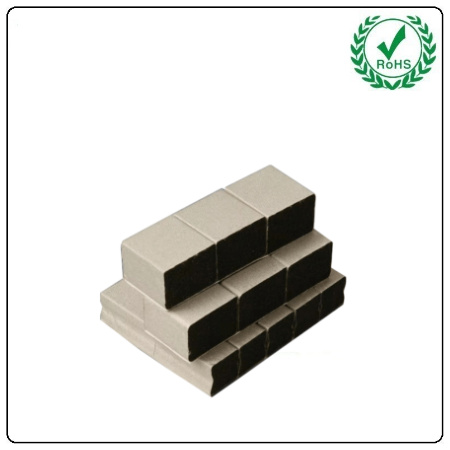

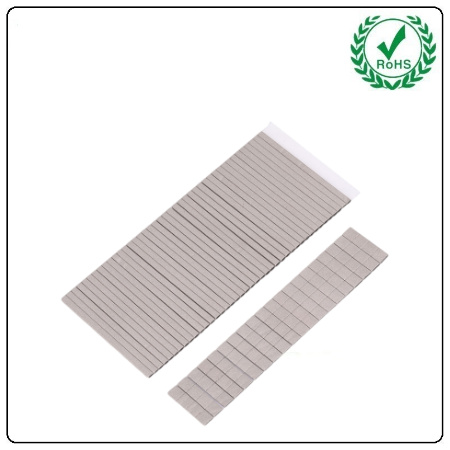

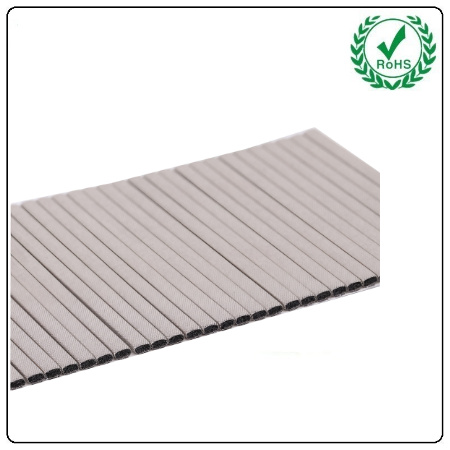

| Conductive Foam | Highly flexible, excellent compression recovery, superior shielding performance, with sealing and cushioning capabilities | Foam gaskets, die-cut pads, conductive strips |

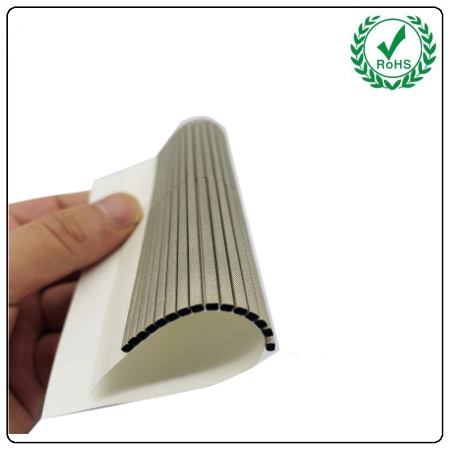

| Conductive Fabric Tape | Lightweight, flexible, and conformable, suitable for curved/irregular structures | Conductive Fabric Tape, Die-Cut Shielding Adhesive Pads |

| Conductive Rubber | Excellent thermal properties, strong sealing capability, and resistance to aging, suitable for harsh environments. | Rubber Sealing Ring, Shielding Gasket |

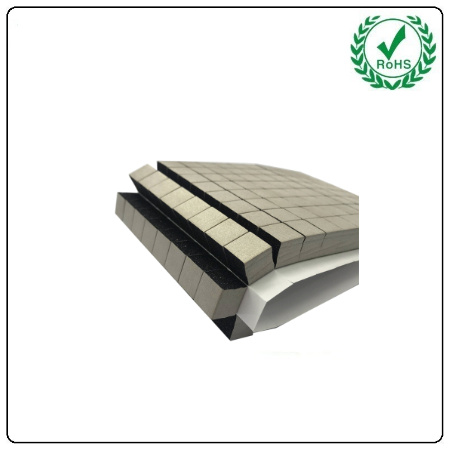

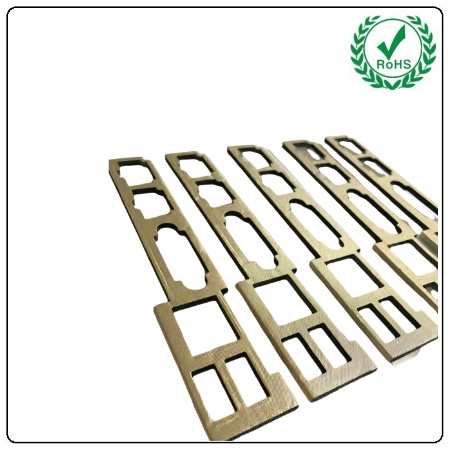

| Metal Foil / Metal Foil Foam | Exceptionally high electrical conductivity, outstanding shielding performance, lightweight and rigid | Metal foil tape, composite foam gasket |

Conductive foam, conductive fabric tape, and metal foil composite foam are core categories for die-cutting processing. They can be die-cut to any size or shape according to customer requirements and directly integrated with electronic components/parts such as switches, connectors, PCB boards, and equipment enclosures.

Key Performance Indicators for EMI Shielding Materials:

1. Shielding Effectiveness (SE): A core metric measured in dB (decibels), indicating a material's ability to attenuate electromagnetic waves. Higher values denote superior shielding performance.

2. Conductivity: The lower the resistivity, the better the conductivity and the stronger the reflection attenuation effect;

3. Mechanical Properties: Flexibility, compression recovery rate, tensile strength, bendability, compatibility with device mounting structures (e.g., narrow gaps, curved surfaces, areas requiring compression);

4. Environmental Adaptability: Temperature tolerance range (–55°C to 200°C is mainstream in electronics), thermal aging resistance, moisture/heat resistance, salt spray resistance, suitability for outdoor/harsh environments like automotive and industrial equipment;

5. Processing/Installation Characteristics: Die-cutting capability, adhesive backing strength (if coated), and adhesion properties determine suitability for mass-production die-cutting and equipment assembly;

6. Additional Functions: Certain applications require materials to integrate sealing, cushioning, and thermal conductivity (e.g., new energy battery packs, in-vehicle equipment), i.e., “shielding + thermal conductivity + sealing” composite materials.

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}